Pipe Coating

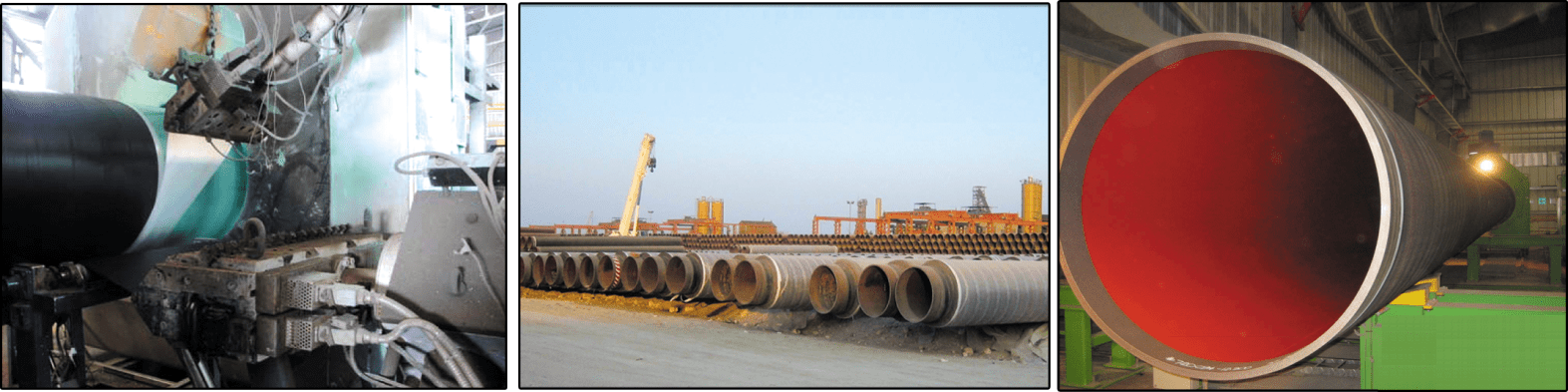

Pipecoating Plants

PETROJET owns & operates (3) pipe coating plants in Suez and Port-Said to serve the projects’ needs of anti-corrosion pipe protection in Egypt & abroad using different types of coating systems such as:

- External Anti-Corrosion Coating according to (ISO 21809-1/ DNV RP-106 / NF A49-710-711)

- Internal Flow Coating according to (API 5L2)

- Concrete Weight Coating according to (ISO 21809-5)

- Fusion Bond Epoxy according to (ISO 21809-2 / NACE RP 0394)

1- THE PORT SAID POLYETHYLENE COATING PLANT WAS ESTABLISHED IN 1985 AND COMPRISES (3) COATING LINES:

- P.E and P.P Anti-Corrosion coating Line Ranging: (3” -52”) Pipes Diameter with a coating capacity of 7000 m2/D

- Internal lining epoxy coating Line Ranging: (8” -52”) Pipes Diameter with a coating capacity of 6000 m2/D

- Fusion Bond Epoxy Coating Line Ranging: (3”-52”) Pipes Diameter with a coating capacity of 4000 m2/D

2- PORT SAID CONCRETE COATING PLANT WAS ESTABLISHED IN 1985 AND COMPRISES (2) COATING LINES:

- Polyurethane foam (PUF) Ranging (6”- 32”) Pipes Diameter with a coating capacity of 1100 m2/D

- Concrete Coating (2 Coating Lines) Ranging (6”- 48”) Pipes Diameter with a coating capacity of 2000 m2/D

3- THE SUEZ COATING PLANT WAS ESTABLISHED IN 1984 AND COMPRISES (3) COATING LINES:

- P.E and P.P Coating line Ranging (4”- 36”) Pipes Diameter with a coating capacity of 2000 m2/D

- Internal lining Ranging (12”-36”) Pipes Diameter with a coating capacity of 1500 m2/D

- Polyurethane foam (PUF) Ranging (6”- 32”) Pipes Diameter with a coating capacity of 1100m2/D