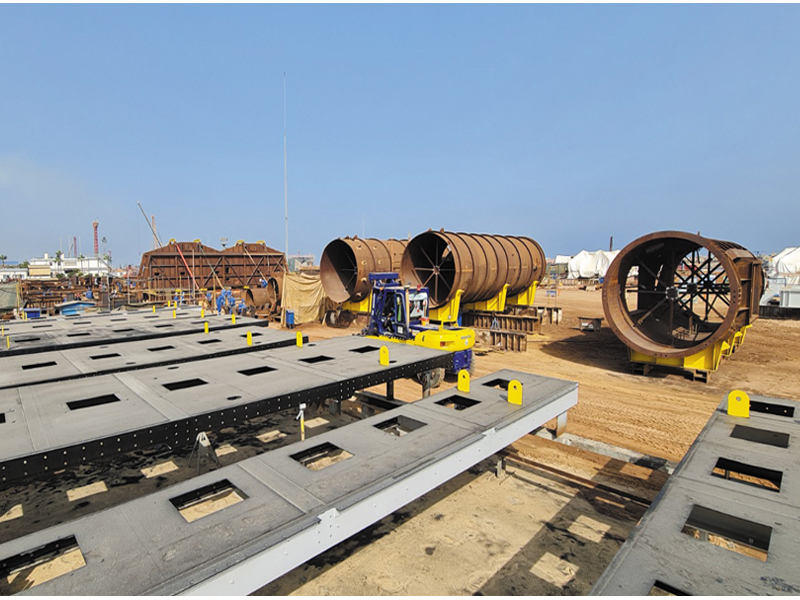

YANBU GAS PLANT EXPANSION

The primary objective of the project is providing facilities to process the additional C2+NGL volumes generated from 2006 – 2010 Business Plan crude increments, as well as providing feedstock supply to the petrochemical industry at Yanbu’ Industrial and the PETRO-Rabigh complex. The project will increase Yanbu’ Gas Plant ethane capacity, as a petrochemical feedstock, from 390,000 bpd to 585,000 bpd by installing a new De-Ethanizer column system and ancillary equipment.